Mitigating Supply Chain Disruptions with Pepperi

May 15, 2023 By Yana Persky

In today’s global economy, supply chain disruptions are becoming increasingly common and can lead to a shortage of products and create a chaotic situation for both businesses and consumers.

According to a report by McKinsey & Company, shortages and supply chain disruptions led to an average 1.3% reduction in sales growth for FMCG companies in 2021. This has prompted businesses to seek out solutions to mitigate supply chain disruptions and ensure business continuity. Are you one of these businesses? Are you taking steps to minimize disruptions? What features or technologies are you using to optimize your supply chain operations?

It’s important that businesses have access to affordable and practical solutions that can help them optimize their supply chain and minimize disruptions. That’s why in this blog post, I’d like to share some real examples of how Pepperi customers have successfully achieved greater supply chain resilience and efficiency.

Reserved Orders

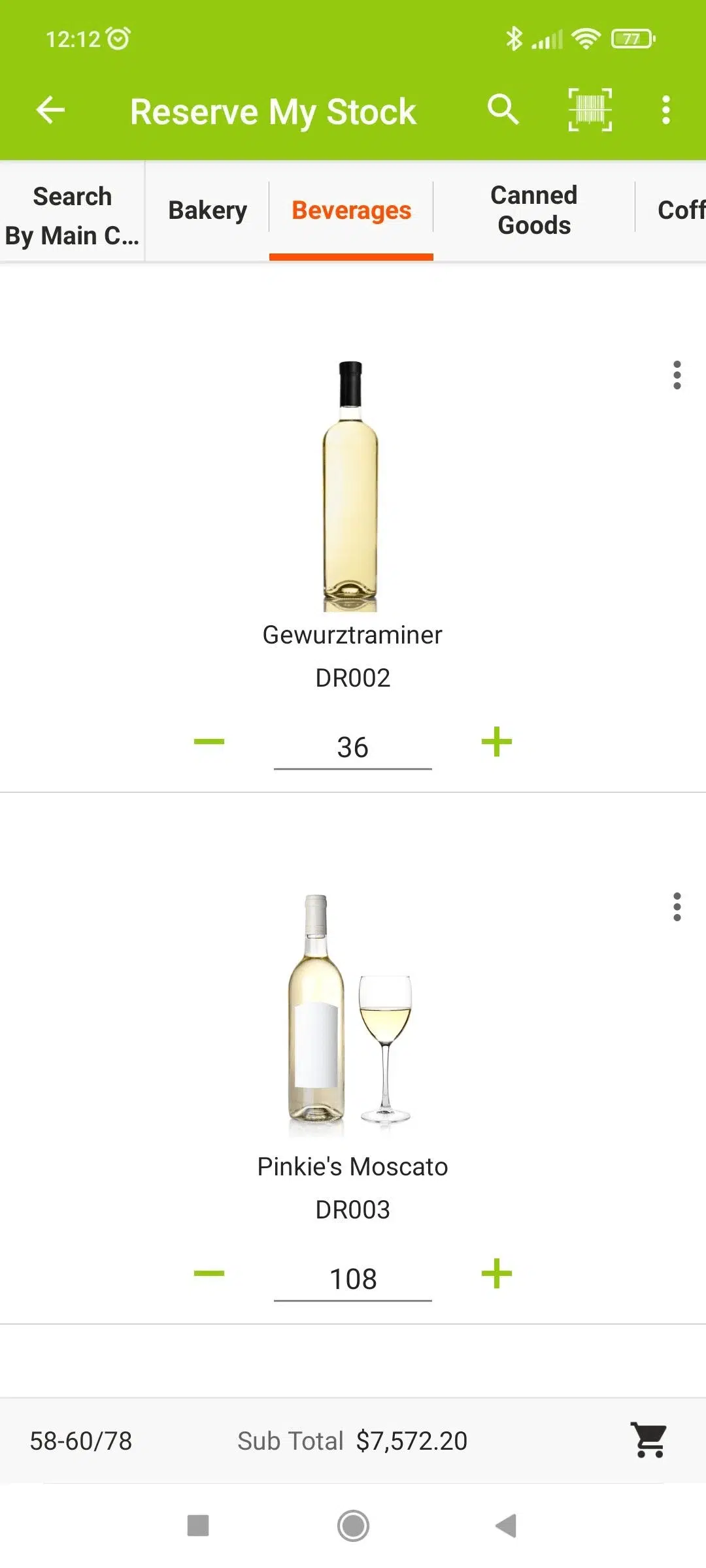

One tool that distributors can use to try to mitigate supply chain risks is by offering something called ‘reserved orders’. This is where buyers can place orders for products that will be stored in the supplier’s warehouse until requested for release.

Reserved orders are particularly useful when there are long or unknown delivery times from the manufacturer. By reserving inventory, buyers can ensure that they will have access to the products they need without risking stockouts. This is especially important for taking advantage of seasonal promotions and special deals, and where demand can be unpredictable and orders need to be placed in advance to secure inventory.

When a buyer decides to reserve inventory, they can choose the specific products and quantities they need. The distributor will then keep the reserved inventory in their warehouse until the buyer is ready to release it. This means that the buyer can effectively hold inventory, often without incurring the cost of storage and logistics.

Reserved orders also offer flexibility and peace of mind to buyers, as they can release inventory as needed. For example, if a buyer expects a sudden increase in demand for a particular product, they can release some of their reserved inventory to meet that demand without having to place a new order and wait for it to be in stock.

Maximum Order Limitation

Another way to mitigate supply chain disruptions is to prevent a single customer from hoarding a disproportionate amount of the available inventory.

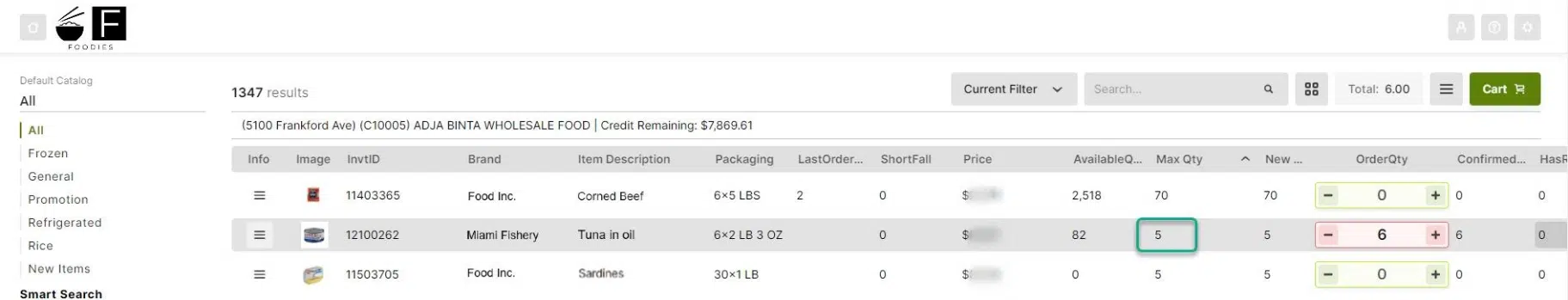

To achieve this, we’ve seen some of our FMCG distributors set a maximum quantity for certain warehouse SKU combinations in a single sales order.

What are warehouse SKU combinations?

Before we dive into the importance of setting maximum quantities, let’s first define warehouse SKU combinations: SKU, or ‘stock keeping unit’ – a unique identifier assigned to a product by a retailer or wholesaler. SKUs help in tracking inventory levels and sales data.

A warehouse SKU combination is simply the combination of a specific product SKU and the warehouse where it is stored.

Why set maximum quantities for each warehouse SKU combination?

Setting maximum quantities for each warehouse SKU combination is an effective way to manage inventory and prevent hoarding. When a particular product is in high demand and has limited supply, it’s common for some customers to try to buy as much of it as possible. This can result in other customers not being able to get the product, which can lead to unsatisfied customers and lost sales.

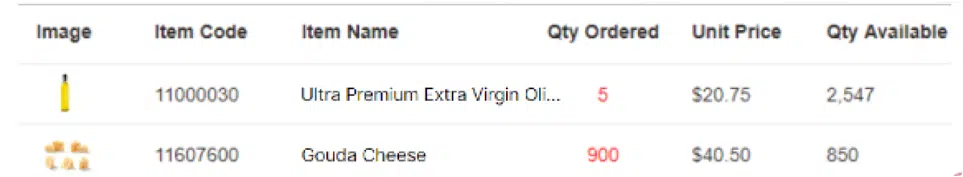

By setting maximum quantities for each warehouse SKU combination, wholesalers can ensure that all their customers get a fair share of in-demand products. For example, if a wholesaler has 100 units of a particular product SKU stored in a warehouse, they can set a maximum quantity of 10 units per sales order. This means that no single customer can buy more than 10 units of that product SKU from that warehouse in a single sales order. The example below shows how a maximum quantity for each warehouse SKU combination can be set in a single sales order.

Multi-Warehouse Inventory

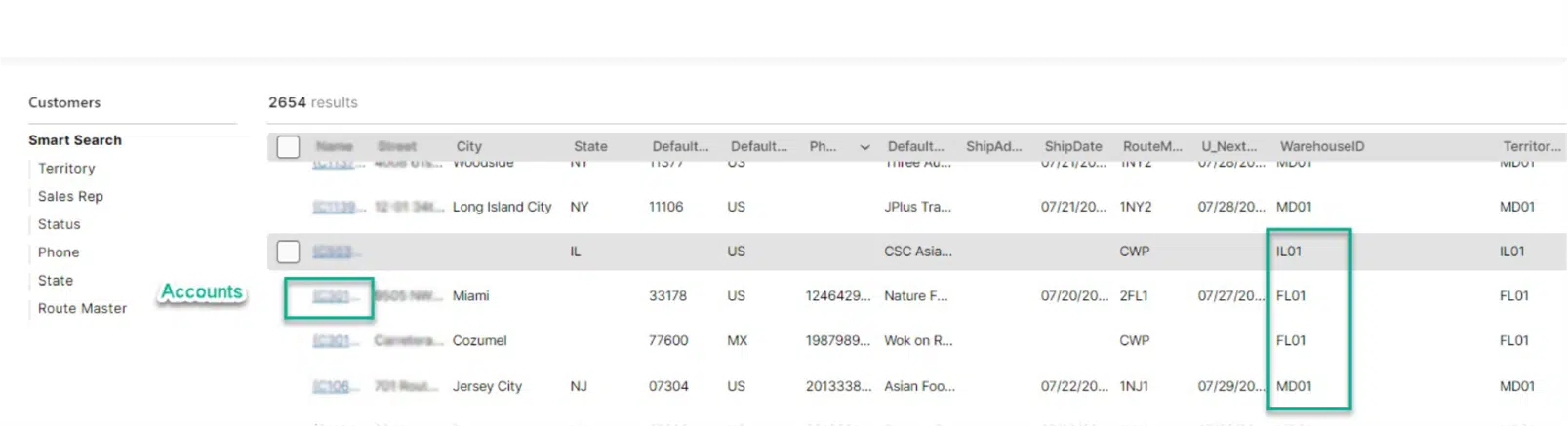

Limiting orders to a specific warehouse can help mitigate supply chain disruptions by ensuring that inventory levels are properly managed and that orders are fulfilled efficiently. By assigning each account/sales rep to a specific warehouse and limiting the order quantity for a SKU to the available stock at that warehouse, businesses can better manage their inventory levels and prevent stockouts or overstocking.

For example, let’s say a business has multiple warehouses located in different regions. If a particular SKU is in high demand in one region but not in another, the business can limit the quantity of that SKU that can be ordered in each region to the available stock at the respective warehouse. This helps ensure that each region has access to the inventory they need while preventing overstocking in regions where the demand is lower.

In the event of a supply chain disruption, limiting orders to a specific warehouse can also help businesses prioritize their inventory and ensure that the most critical customers or regions are served first. For example, if a particular warehouse experiences a delay in receiving inventory due to a disruption, the business can allocate available inventory to the most critical customers or regions served by that warehouse and prioritize their orders accordingly.

On-the-Fly Stock Prioritization

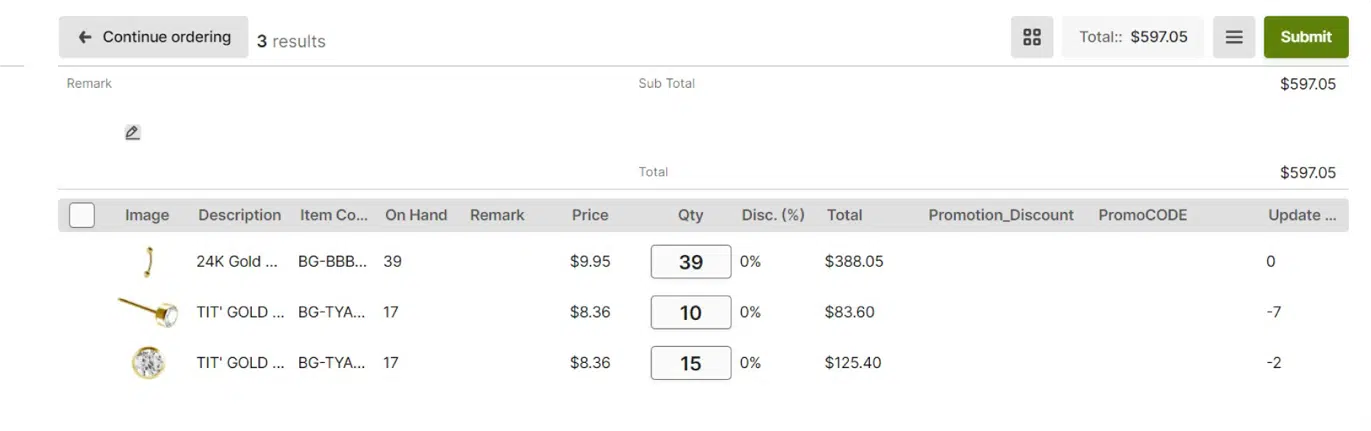

Automatic prioritization of the ‘Quantity Available’ field for carts with multiple duplicate line items of the same SKU is an important feature for mitigating supply chain disruptions. By ensuring that the available inventory is prioritized for the most critical orders or line items, businesses can better manage their inventory levels and prevent stockouts.

For example, let’s say a business has limited inventory for a particular SKU that is in high demand. If multiple line items for that SKU are submitted in a single cart, Pepperi’s automatic prioritization will ensure that the available inventory is allocated to the most critical line items, such as those for paying customers or for promotions that generate the most revenue. This helps ensure that the limited inventory is used in the most effective way possible, minimizing the impact of the shortage on customers.

The validation step that is added to the order submission process is also critical for preventing stockouts and ensuring that customers receive their orders in a timely manner. If the ‘Qty Ordered’ field is greater than the ‘Qty Available’ field for any promotional line item, the submit button will be unavailable, preventing the order from being submitted until the inventory is available or the order is updated.

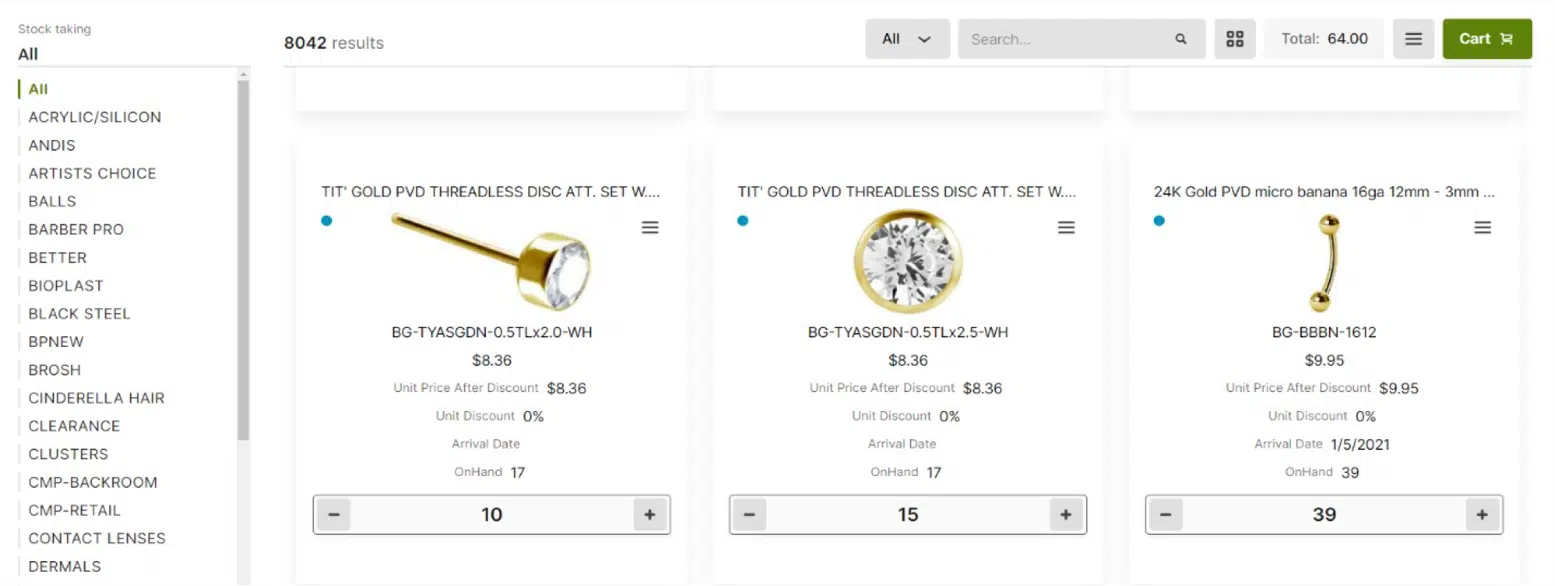

Stock-taking

Implementing a stock-taking feature is a critical step for businesses that want to effectively manage their inventory levels and mitigate supply chain disruptions. By enabling warehouse employees to easily check and update inventory levels, businesses can ensure that they have accurate, real-time data on their available inventory and make informed decisions about their supply chain operations.

For example, one beauty wholesaler implemented a stock-taking feature that allows warehouse employees to quickly scan and update inventory levels using a mobile device. With this feature, employees can easily check the quantity of each product in stock, identify any discrepancies or errors, and make updates to the inventory levels as needed. The updated inventory information is then pushed back into the ERP, ensuring that all relevant parties have access to accurate and up-to-date inventory data.

Moreover, if a particular product is in high demand, the business can quickly identify any shortages and take steps to reorder or allocate inventory as needed. Similarly, if a disruption in the supply chain results in a delay in receiving inventory, the business can quickly identify any potential shortages and adjust their operations accordingly to minimize the impact on customers.

Conclusion

While there are various features and solutions available that can help mitigate supply chain disruptions in the FMCG industry, such as reserved orders, on-the-fly stock prioritization, stock taking, maximum order limitation, and multi-warehouse inventory, not all businesses are able to take advantage of them. This is particularly true for businesses that rely on EDI for their ordering processes, as these features are typically only available through online ordering platforms.

However, the trend in the industry is to minimize dependence on EDI and move towards online ordering platforms, which offer greater visibility, flexibility and control over the supply chain.

By embracing digital transformation and adopting B2B online ordering solutions, businesses can benefit from advanced features and tools which can help them mitigate supply chain disruptions, optimize their operations and stay competitive in the ever-changing FMCG industry. The fact that they can be accessed from anywhere, at any time, makes it easier for businesses to manage their supply chain operations, even when their employees are working remotely or from multiple locations.

Overall, the FMCG industry is evolving rapidly, and businesses that are able to adapt to these changes and leverage the latest technologies and solutions will be well-positioned to succeed in the future. By embracing unified B2B commerce platform and prioritizing supply chain optimization, businesses can mitigate disruptions, improve efficiency and meet the needs of their customers, even in the most challenging of times.